THIS seems an opportune time to kick-start the Kuala Lumpur-Singapore high-speed rail (HSR) project. With the HSR players getting hungry for jobs, both the Malaysian and Singapore governments would have more bargaining chips, in terms of pricing, at least.

The traditional markets for HSR, like Europe and Japan, are almost saturated while new markets like South Korea and China, which have been building up capacity, are now ready to export their technology.

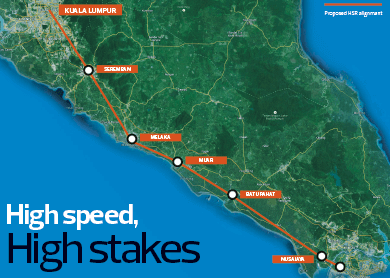

Furthermore, the KL-Singapore rail track could be extended northwards should the relevant governments agree to link Asean to China. This means the train could travel north to Kunming in southwest China, passing through Thailand, Laos and Vietnam, perhaps.

As the government has decided to build the HSR, the next step is to decide on the technology to deploy. This is crucial as a wrong decision would be costly. Switching to a different rail system later could be a pricey affair that the governments and the public will have to live with.

Looking beyond who built the first HSR and who has the fastest speed, Malaysia needs to first understand its own needs.

In fact, the lobbying for the KL-Singapore HSR project is gathering steam. Just two weeks ago, HSR was the top talking point during Prime Minister Datuk Seri Najib Razak’s visit to Japan.

Meanwhile, China, through CSR Zhuzhou Electric Locomotive Co Ltd, has gone one better by setting up an assembly plant in Batu Gajah, Perak.

Stronger lobbying can be expected ahead. Japan’s Sumitomo Corp, which is taking the lead in the project, has already paired up with MMC Corp Bhd, a local partner with a good track record in securing large infrastructure-building works.

The HSR projects in South Korea and Taiwan could be good for comparison, having taken very different approaches to building this costly infrastructure.

South Korea’s project first began in 1992 but suffered long delays due to the 1997/98 Asian financial crisis. It was finally completed in 2003. “South Korea decided to go with French technology, Alstom, since they were willing to partake in technology transfer at the time. Initially, we had to buy everything from France — the rolling stock [trains], the signalling system and the power supply system,” says Cho Byungjae, the Republic of Korea’s ambassador to Malaysia.

“But today, after investing huge amounts of money in research and development (R&D), we have almost 87% localisation for our HSR components. We are fully capable of building our own trains. We no longer have to import from France,” he adds.

The government-funded R&D was carried out through various industry players, universities and research centres. The industry then grew along with the country’s HSR network, which is now 759km long, and counting.

Now that South Korea has developed an ecosystem in HSR, it is looking to export its technology for the first time.

In contrast, being geographically smaller, Taiwan opted to buy the technology from Japan with almost no technology transfer.

The entire 345km-long line from Taipei to Kaohsiung was designed and developed by the Japanese according to specifications given by the Taiwanese government.

It is worth noting that Japan retained tight control of the project, deploying Japanese contractors to manage the civil works. If they take this rigid approach in Malaysia, it might be challenging since local contractors normally take the lead in civil works.

Today, Taiwan still relies entirely on Japan to supply new rolling stock and will continue to rely on it to upgrade the systems and infrastructure. Of course, Japan did transfer knowledge on operating and maintaining the HSR to Taiwan.

Malaysia is more geographically akin to Taiwan. The most HSR Malaysia can build is up to the Thai border, as well as a spur line to the east coast. While that might make a case to opt for the Taiwanese model, it would also make Malaysia reliant on foreign technology.

“By the time we finished the technology transfer, we realised that it was no longer the latest,” explains Cho. “The technology had already evolved and we were still reliant on foreigners for the latest technology. So, we decided to invest in R&D so we would no longer be reliant [on others].”

However, it took South Korea over six years of R&D to catch up with its international peers and be export capable. Supposing Malaysia takes this route, it would be almost 2030 before it is able to catch up. By then, it might be too late in the game to be a serious player, with Asean HSR development being well underway.

Globally, HSR is an asymmetric market with more suppliers than there are projects to undertake and Malaysia will struggle to compete with China’s huge capacity.

Furthermore, Malaysia lacks the high-tech heavy industry support. For example, the high-grade steel required for the tracks would have to be imported.

Nonetheless, one of South Korea’s main strengths is its willingness to export and share its technology with Malaysia. This is easy for it since its government owns most of the technology. In contrast, a lot of the Japanese technology is held by the private sector.

In terms of cost, China is easily the most competitive. CNR Corp has invested in huge capacity that has supported the country’s development of some 15,000km of HSR in the past decade. That said, cheapest isn’t always the best. China’s track record was marred in 2011 when two trains collided, killing more than 40 people.

Just like the Japanese and the South Koreans, the Chinese are state-backed, which gives them a big advantage — they are able to offer funding support for the project.

In this regard, European companies like Siemens AG and Alstom are at a disadvantage, but they cannot be written off yet.

“Alstom is known for comfort and energy efficiency,” explains Filippo Scotti D’Albertis, managing director for Asia-Australasia at Alstom Transport (S) Pte Ltd. “Just because you buy a cheap train at the beginning doesn’t mean the project will cost less in the end. We bring in values like energy efficiency, recyclability and cost of operation — maintaining and running the train, which is below the market average,” he explains.

Likewise, Siemens senior vice-president and country division lead for the mobility division, Shariman Yusuf, points out, “As far as costs are concerned, it has been proven that, taking into account the total cost of ownership, we remain highly competitive.”

Meanwhile, Japan prides itself on the lightweight design of its Shinkansen carriages, which are also highly airtight.

“This allows civil structure (viaducts, tunnels) to be smaller, reducing costs. The low weight also reduces operation and maintenance cost — in terms of energy consumption and track maintenance,” explains the Japanese Embassy in Malaysia.

Beyond all these, there are many more technical variables that will need to be scrutinised. However, there is good news. Malaysia and Singapore are in the driver’s seat in selecting the HSR technology as competition is stiff, so they should have no trouble in getting the best deal possible.

This article first appeared in The Edge Malaysia Weekly, on June 15 - 21, 2015.

Save by subscribing to us for your print and/or digital copy.

P/S: The Edge is also available on Apple's AppStore and Androids' Google Play.