Not many people know recycled cartons can be turned into roof tiles. So, when you recycle your drink pack under the CAREton Project, it helps people in need by providing a roof over their heads. > Manjula

WHEN you get a cup of coffee at The Bee, either at Publika Shopping Gallery or Jaya One, you can be assured that your order generates a smaller amount of waste than if you dined at other establishments. This is because the company behind the restaurant chain recycles all its milk cartons.

These milk cartons are turned into roofing tiles and distributed to social enterprise EPIC Homes, which constructs homes for Orang Asli communities in Malaysia. This is an initiative of Tetra Pak (M) Sdn Bhd’s CAREton Project.

“We got in touch with Tetra Pak in April last year. And after two or three months, [the recycling initiative] got going,” says Jasmin Thum, general manager of Freeform Sdn Bhd, the operator of The Bee restaurants in Malaysia.

“For us, the challenge [in implementing this] was in getting the staff to do the extra work. You have to wash and flatten the cartons before bringing them out. It is more work, but it is good for the company and everyone.”

Tetra Pak first introduced its recycling initiatives in 2005. While the company does not own or operate any collection infrastructure or recycling plants, it acts as a catalyst in the drink pack or carton recycling value chain by cooperating with all the key stakeholders involved. This includes recyclers, waste management companies and public institutions.

“In 2005, it was more the setting up of the foundation for such recycling as there wasn’t any technology to recycle with back then. We work with local recyclers and collectors to see whether they are interested in doing this, as they are the ones that will manage the buying and selling,” says Tetra Pak environment manager Manjula Murugesan.

“The foundation took a long time to build. We had to make sure they were the right people who had the right technology and knowledge to handle it. We don’t just do consumer awareness, we also try to grow the local collection network and recycling capability.”

Back then, the recycling rate in Malaysia was negligible. But there has been immense progress since. At end-2013, the recycling rate had climbed to 17.9%, which amounts to 350 million cartons or 3,898 tonnes of material that had been recycled and turned into new products other than roofing tiles. In October last year, Malaysia’s carton recycling rate stood at the global average of 24%.

Tetra Pak’s collection network has been expanded to more than 27 commercial operators in the country. It also recommends recycling solutions to recyclers and supports technological developments in recycling.

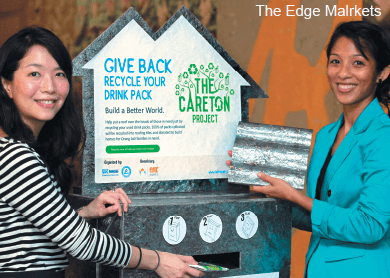

In its effort to increase awareness among consumers that drink packs can be recycled, Tetra Pak launched the CAREton Project in collaboration with Nestlé (M) Bhd. “The project is a collaborative effort between Tetra Pak and Nestlé Milo to promote used beverage cartons for recycling. It started in 2012 to specifically promote drink pack recycling as a consumer awareness project. It became known as the CAREton Project in 2013,” says Manjula.

“Not many people know recycled cartons can be turned into roof tiles. So, when you recycle your drink pack under the CAREton Project, it helps people in need by providing a roof over their heads.”

According to Manjula, the cost of producing a recycled roof tile is cheaper than that of a fibre cement one. A zinc tile might be slightly cheaper, she says, but it lacks heat and noise insulation properties. Roofing tiles made of recycled cartons, on the other hand, provide excellent noise insulation, are fire-retardant and low in water and heat absorption.

The production of a recycled roof tile begins with a carton’s material separation, which is 75% paper, 20% plastic and 5% aluminium. At the carton recycling facility, a hydrapulper process separates the paper or pulp from the plastic and aluminium, or Poly Al. Then, the pulp is sent to a paper-making facility and the Poly Al to a hot press facility. The hot press facility processes the Poly Al into flat panel boards, and grooves are inserted as the boards cool down to create roofing tiles.

It’s a seemingly simple process in theory, but mass volumes of drink cartons are needed to produce sufficient roofing tiles per home. One roofing tile, measuring 4ft by 9ft, requires 7,247 drink packs. Some 46 roof tiles are required to build an EPIC Home, and Tetra Pak’s goal for 2014 was to provide such tiles for 15 homes, translating into a target collection of five million used drink cartons.

To imagine the scale of drink packs needed in terms of consumption, The Bee in Publika collects an average of six to seven cartons per day, and about 12 at its Jaya One outlet.

Recycling efforts, however, went better than expected. In 2013, Tetra Pak collected 3.62 million cartons, 119% more than its target. Last year, it amassed 7.2 million cartons, surpassing its initial five million target. These will be used to form the roofs of 20 EPIC Homes this year.

Roofing tiles aren’t the only things drink packs can be repurposed into, depending on the technology available in the country. According to Manjula, China has the capability to separate all three materials — paper, plastic and aluminum — in a drink pack. The plastic is sold to the oil industry, aluminium to the aluminium industry, and paper to the various industries that make stationery, egg cartons and toilet rolls.

“China has the [carton material] volume, capital investment and cheap labour to invest in such technologies. [The ability to recycle] depends on how much recycling infrastructure you have,” she says. “We are also doing research to see what Malaysia’s plastics industry can do with [the recycled material].”

While Malaysia has made headway since Tetra Pak started its recycling initiatives, challenges remain ahead, the biggest being the collection process. Recyclers or collectors only do pickups from a collection point if there is a minimum of 500kg worth of cartons, as they are mostly industrial collectors.

However, nascent recycling awareness means most parties offering drink packs for recycling do not collect enough of them to make it worthwhile for the collectors to come.

“This is the volume gap we are looking at in Malaysia right now. There are too few collectors and too much waste. More work needs to be done to close that gap, especially since the recycling collection infrastructure here is largely informal. Regulations related to recycling have yet to be enforced,” Manjula says.

“When we work to promote recycling, it needs to have the technology, end product development, collection network and awareness running concurrently to be able to work,” she adds.

It is also important for recyclers to run a profitable business to keep recycling activities afloat, and to make sure the recycled end products are strong.

“Tetra Pak works closely with recyclers because if their business does not do well, they will be unable to create a pool for the waste products. The way they collect [the materials] and recycle has to be efficient. If they don’t have that, their business will die,” Manjula elaborates.

“So, we study the business and figure out what their efficiencies are and what their end products should be, based on what Malaysians need. We need roofing tiles and cardboard paper. That is how we strengthen the recycling dimension in Malaysia.”

In building capacity to better enable carton collection, small and medium enterprises (SMEs) like The Bee can step in by providing an accessible collection point. Thum says taking on this activity has two benefits — the business can make a difference by recycling and use it as an opportunity for brand building.

“This shows we are not just about making money. The Bee joined this so that we could engage with the community and patrons,” she says.

“Nowadays, people are more environmentally aware and they make choices based on that. If they know this is what The Bee is doing, and if they get a coffee here, they know that their demand for coffee will have a positive effect. This way, people will want to support and trust the brand.”

What also makes this work is the support of shopping centre operators. The recycling bins need to be located in a prominent area for all to see, which is usually on the premises. As the shopping centre and its tenants usually have segregated operations, cooperation and agreement need to come from both parties.

“Ideally, we would work with bigger organisations [to collect volume]. If malls come into the picture, their tenants are our best bet instead of looking at on-the-go consumption. Places like Jaya One and Publika have been supportive,” says Manjula.

Tetra Pak welcomes any organisation to be a CAREton Project collection partner. All that is required, Manjula says, is their enthusiasm and support for the project and to make the necessary logistic arrangements in facilitating the collection of drink packs.

“The collection infrastructure in Malaysia is definitely still a work-in-progress. This is why we need to generate greater awareness among commercial partners and consumers. A wider network allows greater accessibility for consumers to recycle and the added convenience is a major factor in generating action,” she adds.

“Likewise, consumers who are more aware of the benefits of recycling will help increase collection volumes and frequency. Recycling is an integral component of Tetra Pak’s DNA. It is not our business, but it is our business to make recycling work.”

To find out more about becoming a CAREton Project collection partner and where the nearest drink pack recycling collection point is, visit www.recycle-easy.com.my.

This article first appeared in Unlisted & Unlimited, The Edge Malaysia on February 9 - 15 , 2015.

Save by subscribing to us for your print and/or digital copy.

P/S: The Edge is also available on Apple's AppStore and Androids' Google Play.