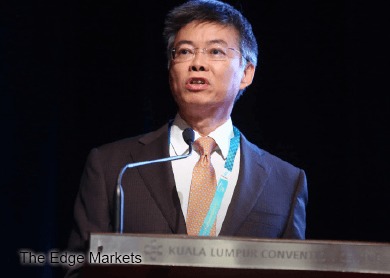

KUALA LUMPUR: Shell Malaysia’s chairman Iain Lo (pic) feels that the oil and gas industry should look beyond cost cutting measures, for instance project deferrals and contract renegotiations, to adapt to the change brought by lower crude oil prices.

“Efforts need to go beyond just cutting costs. We can save costs by cutting or deferring projects, we can renegotiate contracts just to lower rates.

“Yes this will result in lower spend, but it will also give the opportunity to reshape the industry so that we can be more efficient in deploying and utilising our assets. This is so that we are more economical in specifying what is fit for purpose and we will also be more focused on managing risks instead of trying to eliminate it,” said Lo.

Speaking at the 18th Asia Oil and Gas Conference, Lo explained that Shell has been looking into ways to reduce its unit development costs for fields under the development phase as well as ways to reduce unit operating costs for fields that are already in production.

“In the field development space, we are being competitive in scoping facilities that are fit for purpose. We are also more open to accepting industry standards,” he said, noting that there is much evidence that the oil and gas industry is being charged more on certain equipment compared with other industries that use the same equipment, such as pipes and compressors.

Lo said when Shell applies these new approaches, the group has been able to see a capital expenditure (capex) reduction of up to 50%.

“For the upcoming well-head jacket in Sarawak, we see an opportunity for capex reduction of up to 50% compared with jackets that have been previously installed in Malaysia. This is not an insignificant reduction in cost,” he explained.

He said that for fields in the production stage, similar approaches can be done. “But we must look at the other side of the equation and look at means to increase production and availability”.

Lo also noted that Shell has been going through vigorous processes to seek opportunities for its wells, reservoirs and facilities to unlock production or ‘de-bottleneck’ capacity and optimise production.

Shell’s counterpart Petroliam Nasional Bhd (Petronas) has gotten the ball rolling on cost saving through its initiative called the cost reduction alliance initiative (Coral 2.0) which seeks to align the industry to focus on increasing efficiency and lowering costs in key areas such as joint sourcing, common warehousing, standardisation of technical standards and logistics, said Lo.

“Note that these are all structural changes that could lead to significant and sustainable savings for our industry. Success for Coral 2.0 rests in the ability of us to forge a common purpose to create a win-win situation for all industry participants and for us to go with a positive attitude and respect for existing arrangements,” he said.

This article first appeared in The Edge Financial Daily, on May 20, 2015.