This article first appeared in Digital Edge, The Edge Malaysia Weekly on August 23, 2021 - August 29, 2021

Innovation, being an abstract concept, can be difficult to quantify and measure. It can be indicated, however, through metrics such as patents filed and granted. As such, the government urges the local electrical and electronics (E&E) sector to generate more intellectual property (IP) through initiatives such as the National Fourth Industrial Revolution (4IR) Policy Framework.

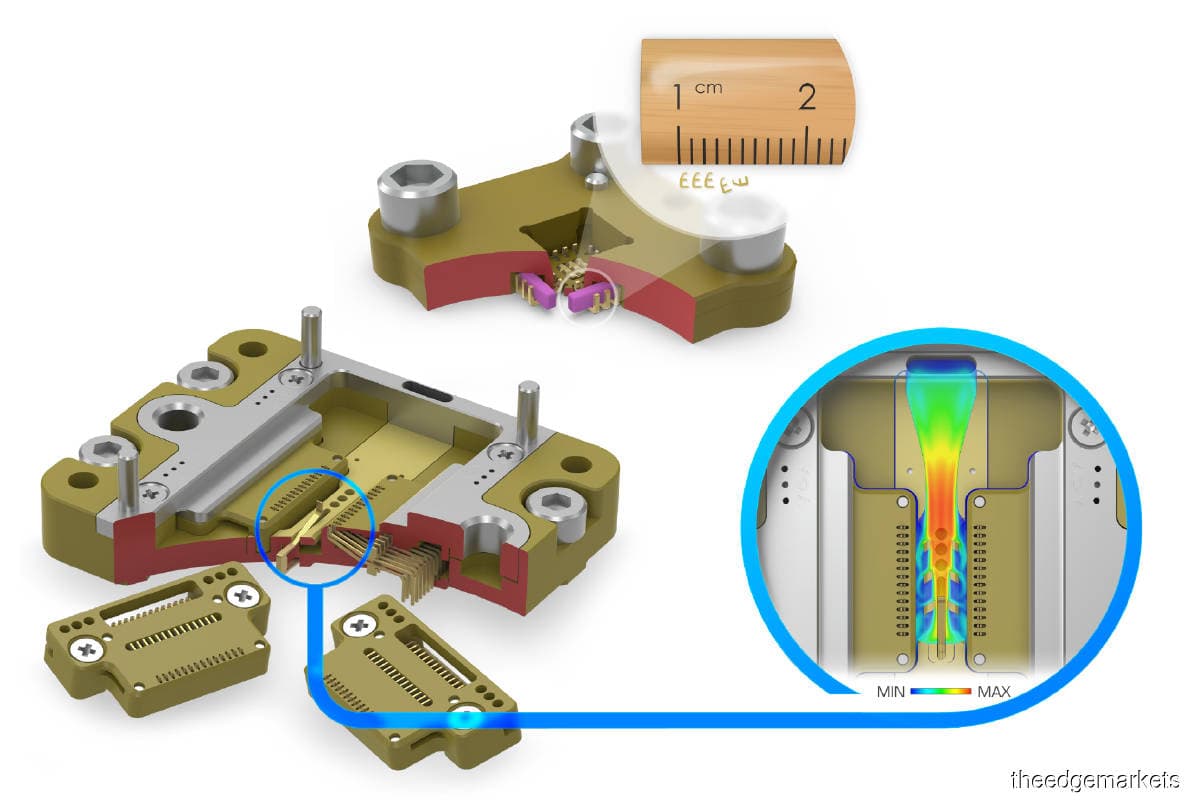

JF Technology Bhd, a local integrated circuit (IC) test contactor manufacturer, has certainly taken notice. In 2011, the company filed for only one patent, which was not granted. A decade later, not only had it filed for 68 patents, a whopping 33 of these were approved. The patents filed are for radiofrequency and cantilever test sockets, used mainly in 5G and automotive applications.

The industry is lacking the proper awareness about IPs and their relative importance, says CEO Dillon Atma Singh. For starters, companies do not spend enough time talking about it, mostly issuing an occasional patent announcement.

JF Technology puts particular emphasis on patent filings, as the company is placed at the forefront of technology in the semiconductor industry, he says.

“We are the first point of contact for first-of-its-kind semiconductor devices: If an IC maker designs the chip, we are already in the picture. To protect our IP, we place a huge emphasis on patenting unique inventions in each of the geographical markets we serve,” he adds.

Test contactors, or test sockets, are consumables that physically hold the IC in place while undergoing testing. They require swapping out after a certain amount of use and are made out of extremely tiny components a fraction of the size of a 5 sen coin. These contactors are seldom available off-the-shelf — mainly built according to specifications provided by IC makers.

“For example, if a chip needs to be tested to see whether it can withstand 125 degrees Celsius, our test contactor needs to enable the kind of environment and maintain that level of temperature with a high level of accuracy. These customisations happen all the time because different customers have different requirements,” Dillon adds.

The testing industry generally evolves alongside the semiconductor industry. As technological devices get more sophisticated, semiconductors demand higher frequency and temperature requirements, which in turn requires different test contactors. This opens up plenty of opportunities for the company to come up with new products, and ensure that their IPs are well protected through patents.

“As part of our design team, you cannot be a follower and play catch-up with the rest of the industry. We have to be one or two steps ahead of the customer, anticipate what they need in the future and start working on the designs ahead of time,” says Dillon.

“This drives more innovations and designs that will subsequently be patented. This is also right on top of fulfilling the customer’s existing requirements.”

The company is currently considering licensing agreements with prospective partners as a way to monetise the IPs it currently has. These patents not only lay a foundation for the company’s future financial and earnings growth, but are also a form of recognition for the designer team’s efforts, as they will have their names attached to the patents, says Dillon.

The process

Coming up with a patentable design is not as simple as conjuring a series of ideas and throwing them at the wall to see what sticks.

Key factors to consider include the product’s unique value proposition, the market value and size of the target geographical area, and how likely customers are willing to adopt the new design. The company also needs to consider the possibility that the product will become obsolete within one or two years, instead of the expected 10 years.

To address these concerns, JF Technology formed a cross-functional team comprising the company’s top management and major shareholders. The team meets up regularly, explores these considerations and ensures that the IPs generated will achieve commercialisation at the end of the day.

Leading them is engineering director Shamal Mundiyath, who also heads the company’s product design and development team. The first step involves coming up with an initial design that is distinctively unique while still adhering to customer requirements.

“If we look at the national IP database, there are thousands of patents filed and granted each year. We cannot trespass the boundaries of someone else’s existing patented product and subject,” says Shamal.

“We conduct very detailed studies and long brainstorming sessions, such as the SWOT analysis, which explores the strengths, weaknesses, opportunities and threats of the design. We discuss the design requirements, its current failure and successes. We decide to go ahead with filing a patent only after obtaining a consensus from the team.”

Once an initial design is ready, Shamal will approach the group’s manufacturing manager Lee Eng Kiat to see whether the manufacturing process is feasible and can be done cost effectively. Then, the discussion moves to how the product can be marketed and sold, which involves the sales and marketing team.

The next stage involves the actual process of filing the IPs, which Lee is also in charge of. The patent filing process generally takes two to four years, from when it is first initiated until the patent is granted. Filing for patents does not require a team of lawyers, but employing the services of a patent agent helps tremendously with many of the steps, he says.

“The first thing we need is a patent write-up. We are not familiar with the legal language involved but, fortunately, we do not need to write it. We engage patent agents who will help us write based on our input, designs and the features of the product,” says Lee.

“We first file it in Malaysia, because we are a Malaysian company, through the Intellectual Property Corporation of Malaysia (MyIPO). Within a year, we need to file it in the other countries where we plan to sell it because we cannot do so after the one-year period. For example, if we sell to the US, China, Taiwan and the Philippines, we request the patent agents to file in these countries within a year.”

While the patent applications are being examined, Lee says, there are likely to be objections and additional questions from the patent examiner. The company has to convince the examiners in writing, through a series of phone calls or both. If the invention is novel enough, the patent certifications will then be issued.

Lee also points out that companies do not need to wait until the patents are fully granted before commercialising the product. If the patent is filed in 2021 but was granted in 2023, the patent effectiveness is backdated to the day it was filed.

Although patent filings in multiple countries may seem complex at first glance, Lee says the process is mostly the same worldwide. The biggest difference in filing for patents in different countries lies in the speed rather than the process itself.

“Developed countries such as China or Singapore have more resources to examine your patent applications, and the patents are granted within one to two years. In Malaysia, it takes slightly longer, maybe three to four years. [The wait time for approvals] correlates with the expertise of the patent examiner and the availability of subject matter experts,” he explains.

Lee adds that there are ways to handle the times when the patent examiner believes the invention is not novel enough and points out similarities with existing patented designs.

“One way is to revisit your invention and claim other features. For example, if you are filing for a patent to claim features A to E, the examiner might point out that features A and B are not novel. We can narrow down the claim to only features C, D and E,” he says.

“Over the years, we have learnt to conduct a thorough patent search beforehand, be it ourselves or through the help of patent agents. This is to ensure that, once we file for patents, we manage to hit the right spots. This is such that, if we file for features A, B and C, we can get all three granted as well.”

According to Dillon, it is difficult to single out a particular process that is more challenging than the other. He says designing test equipment for complex semiconductors is a challenge in itself, and coming up with the logistics behind the manufacturing process is equally as tough.

To have a streamlined IP filing process, he stresses the importance of team coordination and the ability to work across different functional groups to see the process through from beginning to end.

“Sometimes, companies want to come up with the perfect design or product before they start filing for the IP. Instead of perfection, it is more important to figure out whether the IP is ready to be filed,” Dillon explains.

“Because the longer you wait, the more likely it is that somebody else might already file for the patent and then it will be too late. So, do not wait to come up with the perfect product.”

Save by subscribing to us for your print and/or digital copy.

P/S: The Edge is also available on Apple's AppStore and Androids' Google Play.