This article first appeared in Enterprise, The Edge Malaysia Weekly on June 12, 2017 - June 18, 2017

When the team at Universiti Malaya lit up its first blue light-emitting diode (LED) in January last year — just two months after signing up for the project — it sent waves of delight throughout the industry. It is notoriously difficult to get the right recipe of ingredients to light up an LED and most of the major corporations guard their recipes like Coca-Cola protects its formula.

A series of serendipitous events had come together to make this possible. First, there was Nobel Prize winner Shuji Nakamura’s visit to Malaysia at a crucial time. Second, UM already had its own Metal-Organic Chemical Vapour Deposition (MOCVD) machine, which would allow it to grow the epitaxy layer on a substrate. Then, there was the presence of Dr Ahmad Shuhaimi Abu Bakar at University Malaya, who had already worked on LED technology in Japan. Finally, University of California Santa Barbara (UCSB) sent its postgraduate students to UM to help replicate Nakamura’s laboratories at the university.

What UM is trying to do is find a way to grow gallium nitride (GaN) on a base layer of GaN, which would lead to more efficient LEDs, on a commercial basis. Sivanathan Periasamy, a master’s degree student who is working with Shuhaimi on the project, explains the process. “If you want to grow LED on the epitaxy layer, you need a base layer, known as a wafer or a substrate. Before, we used silicone. Then, it was sapphire. Now, it is GaN,” he says.

GaN substrates are incredible expensive. “The two-inch substrates cost US$2,000 to US$3,000,” says Siva. It is much cheaper to use sapphire, which costs US$10 for a single wafer.

That is why Shuhaimi, the principal investigator on the UM team for this project, is interested in growing the GaN substrate as well. Sapphire substrates have a defect density of 109 while GaN substrates have a defect density of 106. The lower the defect density, the more light the LED can produce.

“We are trying to source the GaN substrates from different suppliers because they have different rates of defect densities. The recent one from China is less than 106, so we really want it because with this substrate, we can increase the light density tremendously,” says Shuhaimi.

Previously, these substrates were only available from Japanese companies such as Sumitomo Corp, Mitsubishi Chemical Holdings and Hitachi Cable Co Ltd. It is a huge and lucrative market, which is why Shuhaimi thinks the university should go into it.

“We have grants coming from Collaborative Research in Engineering, Science and Technology (Crest) to develop our own substrates because the market for substrates is quite big. Nobody really sees it except for those working with LEDs. We want to have the minimum defects possible. One two-inch substrate costs about US$3,000. If we develop it ourselves, it will cost less than US$100,” he says.

Shuhaimi says the machine will cost RM2 million. “But from that RM2 million, we can produce another RM1 million. We spend RM3 million to RM5 million on other equipment and it takes time to make money. And besides, we cannot use R&D equipment to make money. But it is different with the substrate equipment because the equipment we are buying can already produce commercial substrates.”

It is not only expensive to get the GaN substrate, you have to jump through hoops to get it because it is a controlled material. Kamarul Allif Kamarulzaman, a master’s degree student who is on Shuhaimi’s team, recalls that it took a year between applying to import the material and actually receiving it, even though it was only from across the Causeway. “The materials we use can be used to make weapons of mass destruction, so we need to get a licence from the US Department of Commerce,” he says.

Because of Shuhaimi’s experience in Japan (see accompanying story), he has good contacts in the industry and was able to set up his lab at UM for a fraction of what other universities would have paid. He and his team were given an old abandoned building at the university and about RM600,000 to refurbish it and build a clean room.

“We utilised the money efficiently. If you ask other universities, they would not even be able to build a clean room because that alone costs more than RM1 million,” says Shuhaimi.

“But we have all the best pricing because we know people and we negotiate a lot. I do that myself. If the Malaysians do not give me the price I want, I contact my colleagues and professors in Japan and they will help. Now, our network is even bigger; we know the Taiwanese, Chinese, Singaporeans and Americans involved in this field.”

When the project was announced, the only university involved was Universiti Sains Malaysia (USM) in Penang. UM was not even on the radar screen because the related agencies were not aware of the kind of research taking place there.

“I joined UM in July 2010. In October that year, the previous director of this research centre went for a wedding ceremony with the vice-chancellor, who asked him to apply for funding for high-impact research. Our initial proposal was for RM13 million to buy the MOCVD, but this was cut to RM9 million,” says Shuhaimi.

Several factors made it possible to bring down the price of the MOCVD. First, he was able to negotiate it down from US$1.48 million to US$1.1 million. Then, Japanese Prime Minister Shinzo Abe devalued the yen. So, instead of costing RM5.8 million, the MOCVD only cost RM3.8 million.

“That was for the equipment. The gas lines were a separate contract. It was RM1.2 million in total. So, we paid about RM5 million for this system, including the gas piping,” says Shuhaimi.

UM was initially not invited to participate in the GaN on GaN project. “The government planned the GaN on GaN project in February 2014. I joined its meeting during a Value Management Lab with the Economic Planning Unit. It was already in the proposal form, but we had not been invited. The project had been designed for USM,” says Shuhaimi.

The project was led by Crest. “They came to visit and when they saw our MOCVD system, they asked us to be a part of the project. When they invited us to join, I negotiated for three pieces of equipment to complete our fabrication lines,” says Shuhaimi.

With the MOCVD, the team can produce layers on top of the waters. But it needed additional equipment to turn the LEDs into devices.

Shuhaimi says the additional equipment will cost about RM3 million. UM officially embarked on its GaN on GaN programme in November 2015. The first UCSB postdoctoral researcher Dr Li Hongjian was sent to help. Just two months later, they managed to light up their first blue LED. And in April last year, they packaged the LED.

“By March, we had another batch of LEDs. In August, we had our third batch — our best so far,” says Shuhaimi.

Between March and August, the team had some issues. “We were using an inline purifier that deteriorates over time — it gets saturated after one or two months and does not do the job properly, so all the bad gas goes into the system. That was why progress was slow after the March update. We used our internal funds to purchase an ammonia purifier and after that, the performance was much better,” he says.

By “performance” he is referring to the intensity of the light, which is measured in lumens per watt. “Previously, it was 59.6 lumens per watt. We are looking to increase that to 120 lumens, which is good enough for commercial use,” says Shuhaimi.

Prof Dr Rofina Yasmin Othman is director of the University of Malaya Centre of Innovation & Commercialisation, which functions like Crest within the university. “My role is to connect industry with researchers,” she says.

Rofina says there is a lot of good research taking place at UM, but much of it is not publicised. She would like the rest of the world to know about it.

“All this (the collaboration between Crest and UM) started from the fact that we have a great LED programme, looking at the fundamental aspects of the research. We have always been an academic leader in photonics research and more recently, we moved into LED and formed something called the Low Dimensional Materials Research Centre,” she says.

“This group invested quite heavily in training new academic staff such as Shuhaimi as it was already ready to receive the blue LED technology when we signed the collaboration agreement.”

There are two UCSB postdoctoral researchers — Dr Stacy Kowsz and Dr Michel Khoury — and a master’s degree student, Christopher Pynn, stationed at UM. Dr Li has returned to the US, but he will come back to Malaysia next month with his wife, who will pursue her doctorate at UM.

Shuhaimi says there are 12 students working at the lab, six of whom have PhDs. Kowsz has been here since October. She did her PhD with Nakamura and is now under the supervision of Prof Steve DenBaars.

When asked how efficient GaN on GaN is compared with GaN on sapphire, Kowsz says there are no figures yet. “That is why we are doing research on it because the answer is, we really don’t know. In theory, they are making more perfect crystals of GaN on GaN, so these should make more light.”

There are a lot of different things to be developed before you can do GaN on GaN properly. “First, we need to grow the different layers of materials and they have only recently started on that. Then, you have to take that wafer of that material and make that into LEDs. You put contacts in and probe it, and you put in a package so you can get a lightbulb,” she says.

Kowsz points out that you cannot compare the efficiency of GaN on GaN with other LEDs until you go all the way to the last step with actual lightbulbs. “We know LEDs are much more efficient than incandescent lightbulbs or even fluorescent lighting because they have made LED lightbulbs and they have made fluorescent and incandescent lightbulbs and could test them.”

LED displays would be a major application for the new technology. “Displays right now are pretty inefficient, which is why your phone battery is always dying,” says Pynn. “A lot of that energy just goes to your screen. If you can make your screen more efficient … That also applies to your computer, television screen and laptop.”

He points out that the LEDs that make up the displays today are about 5% efficient. “That is because there is a lot of colour filtering that goes on to make the picture a different colour. The stuff that we were doing back at UCSB does involve reimagining what a display could look like and what the underlying efficiency of the LED could be, which is much higher than 5%.”

Khoury will be handling the fabrication side after the epitaxy growth. “They are going to send the chips to Penchem Technologies Sdn Bhd and Inari Technology Sdn Bhd for packaging. We will do the epitaxy and fabrication and they will do the packaging.”

Note: This is part two of the blue LED story that appeared in our May issue

A SERIES OF FORTUNATE EVENTS

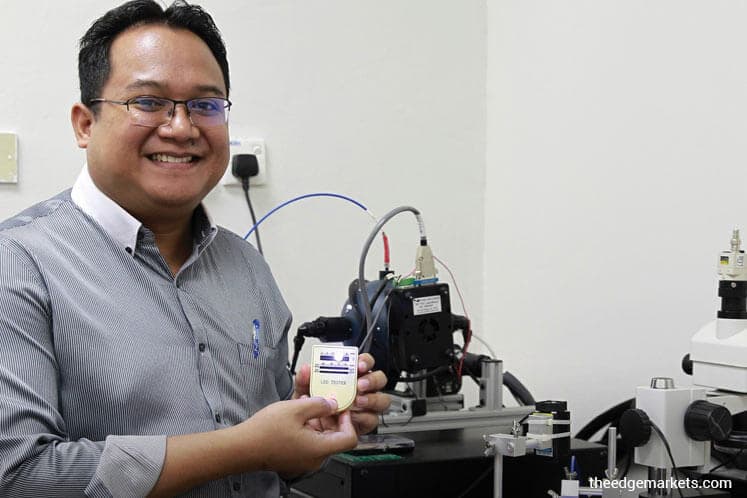

Dr Ahmad Shuhaimi Abu Bakar, who leads the Universiti Malaya team on the gallium nitride (GaN) on GaN project in relation to growing blue LED crystals, has been working with GaN since his postgraduate days in Nagoya, Japan.

“In Nagoya, I did my master’s degree in electrical and computer engineering. For my master’s degree, I focused on electronics and my field was mechanical, electronics and kinetics engineering. But my major was in electronics. Since my master’s degree, I worked specifically in GaN for laser diode applications. I would fabricate laser diodes in Nagoya, together with people from Hitachi Central Labs in Tokyo,” he says

At the time, Hitachi was quite late to the blue laser market, which was dominated by Sony, says Shuhaimi. “Sony had been using blue lasers for its PlayStations since 2005, I think. In fact, Sony’s PlayStation 3 uses blue lasers based on GaN technology.”

He found it very hard working with laser diodes because Hitachi was quite behind in this field compared with companies such as Sony and Nichia. In fact, its lab, which specialised in GaN on silicone, was behind the others that were using sapphire or GaN bulk substrates.

“When we bought a GaN substrate for developmental purposes, it was very expensive. A two-inch substrate from Sumitomo set us back the price of one Myvi,” says Shuhaimi.

By the end of his studies, he had achieved lazing based on the GaN substrate, but not the silicone substrate. “Lazing means concentrated monochromatic light. For instance, if we target blue light for 450 nanometres (nm), the light that comes out should only be 450nm and not diffuse. If you target 450nm, the light that comes out could range from 440nm to 460nm in a normal LED; it is quite broad. So, that is the difference.”

After completing his master’s degree, Shuhaimi wanted to switch universities. He was tired of working on silicone because the defect density on this material was too high, but his professors were pushing him to do it.

When he told his professors that he wanted to move, he was offered the opportunity to work on the Metal-Organic Chemical Vapour Deposition (MOCVD) machine. Also, his professors allowed him to work in other fields and not just on laser diodes.

“That was why I entered the PhD programme in the same lab. I already had juniors working under me to proceed with the laser theme. Even though we did not get lazing, we learnt how to reduce the threading dislocation before the quantum wells to get a higher intensity of light,” says Shuhaimi.

They managed to get LEDs on silicone substrates that were 300% brighter than the conventional technologies. “That made things happen for my PhD even though we were not able to achieve lazing,” he says.

By the time he completed his PhD, Shuhaimi had been in Japan for nine years. He was bored. Also, whatever innovations he managed to achieve in Japan would belong to his professors and not to him.

“That was why I decided to come back in 2010. But there were conditions. If I could not get an MOCVD in Malaysia within three years, I would go back to Japan,” he says.

Shuhaimi’s master’s degree had been sponsored by Universiti Malaysia Perlis (Unimap). But when it came to his PhD, he could not find a sponsor because the government policy at the time was only to sponsor undergraduates. “My professors hired me as a research assistant so I could get some money to fund myself in 2007,” he says.

Shuhaimi was not born with a silver spoon in his mouth. His parents were teachers and his elder brother, who worked at Petronas, used to send him about RM3,000 a month. “It was very hard. That was why I applied to Unimap in 2006. The university agreed to sponsor me because it needed staff at the time.”

However, when he came back to Malaysia with his degree, he was aware that if he worked in Perlis, he would have a tough time there. “No one wants to listen to young lecturers from small universities. It is difficult to have any influence from there,” says Shuhaimi.

One of his professors suggested that he apply to “the best university in Malaysia”. So he did. “I emailed the previous Universiti Malaya vice-chancellor my curriculum vitae and he replied within two hours asking me to proceed with the official application. I submitted my job application the next day and immediately got an offer letter from UM.”

That is why he works at UM today and is slowly paying back Unimap for its sponsorship. It is also why he managed to get an MOCVD into UM and was at the right place at the right time when the GaN on GaN project came about.

Save by subscribing to us for your print and/or digital copy.

P/S: The Edge is also available on Apple's AppStore and Androids' Google Play.